Industrial

doors

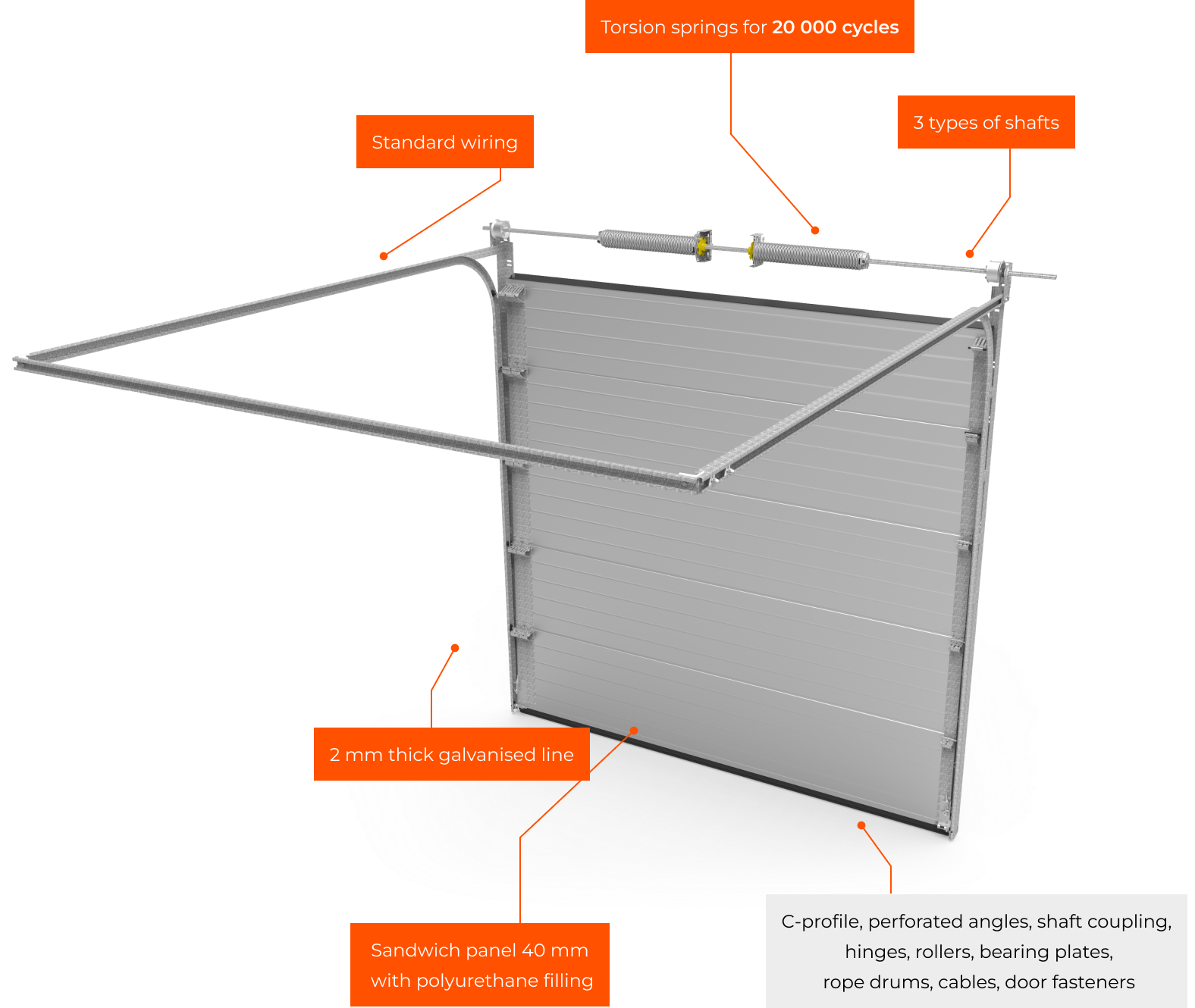

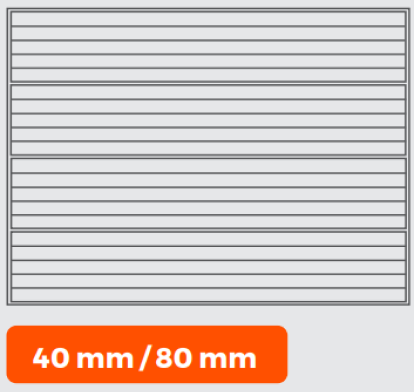

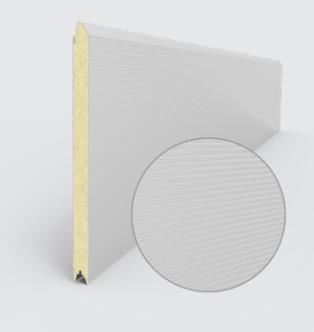

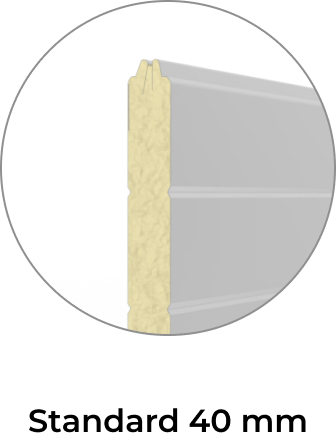

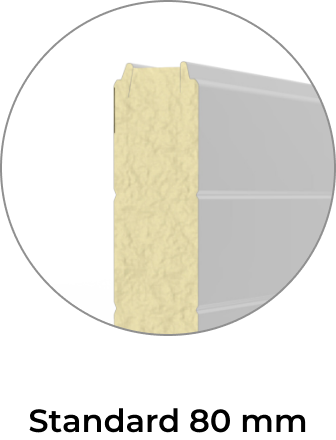

We produce industrial doors made of 40 mm thick sandwich panels in “standard” or “protect” versions. An 80 mm thick panel is also available for the best thermal insulation properties. We supply the door with a wide range of lift types to adapt to any space.

We look at industrial doors not just as an “invisible” part of production and storage halls, but as a quality and reliable product that allows entrepreneurs or business owners to focus on their ideas and plans instead of operational problems.

INDY

Industrial sectional doors

- 40 mm and 80 mm thick panels

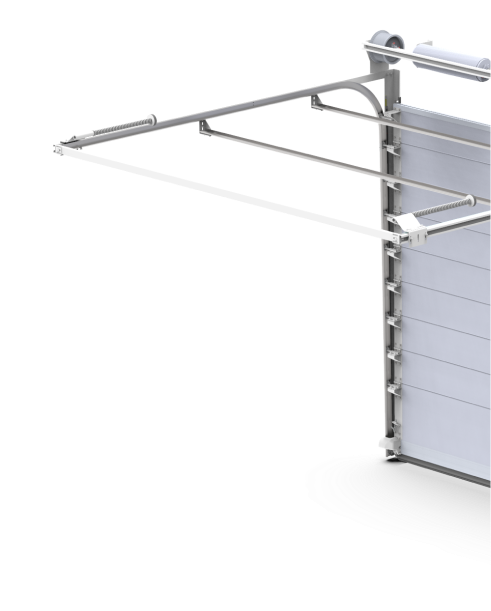

in a wide range of designs and colours - Different lift typrs including horizontal tracks following the roof slope, possibility of pre-assembled shafts

- Option of all-glass aluminium sections with and without broken thermal bridge

- Option of a low threshold entrance door meeting the European standard for an emergency exit

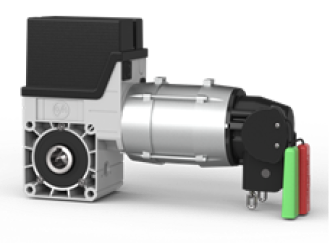

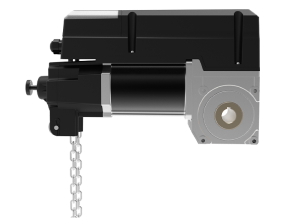

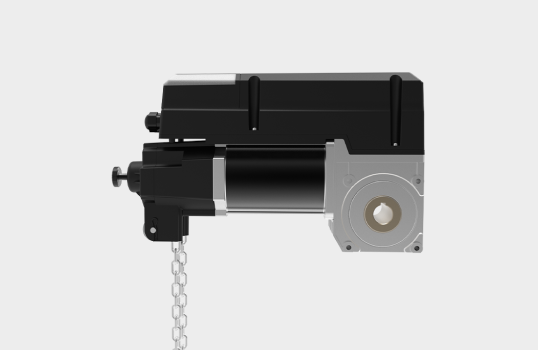

- Wide range of electric motors

- Special solution for underground garages, wet environments (corrosion resistance class C3), food industry, agriculture, aerospace or shipping

Detailed information can be found in our CATALOG.

INDY GT-R

High-speed sectional doors

- Up to 4 times lower energy losses than Indy doors

- Opening speed up to 1.4 m/s

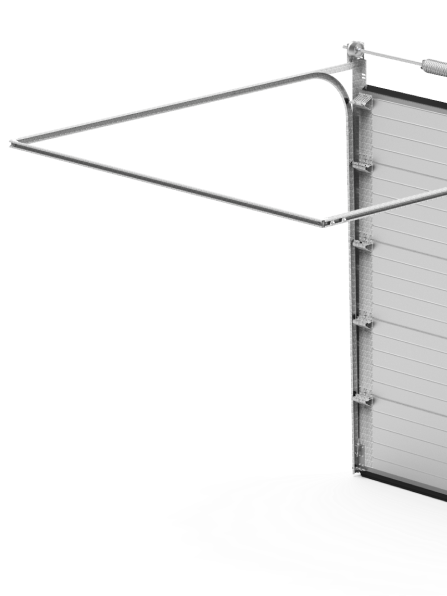

- Different types of track depending on the height of the lintel:

SL, HL, VL - Option of all-glass aluminium sections with and without broken thermal bridge

- High speed motor with frequency converter

- Option of additional accessories for more comfortable control (radar, induction loop, pull switch etc.)

- Efficient use of energy. Calculate how much you can save with the independent door energy calculator.

Detailed information can be found in our LEAFLET.

Basic specifications

TOORS INDY

Quality and reliability are of the utmost importance with TOORS sectional doors. The doors are assembled with high quality materials and parts from the most important European manufacturers. The entire production process is constantly controlled to ensure maximum satisfaction of our customers in all their requirements.

TOORS – doors meet European standards for door technology and are tested according to the standardized EN13241-1 standard.

Panels design standard

Structure

Lamela stucco

Outer color

according to the current panel offer

Inner color

according to the current panel offer

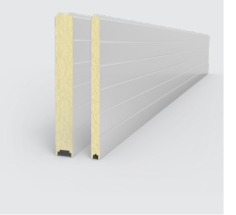

Traditional panel nose shape | polyurethane foam core | hot-dip galvanized on both sides | U (40mm) = 0,50 W/m² K | U (80mm) = 0,27 W/m² K | R = 25 db

Panels design protect

Structure

Lamela stucco

Outer color

according to the current panel offer

Inner color

according to the current panel offer

Finger pinch protection (FSP) | polyurethane foam core | hot-dip galvanized on both sides | U = 0.50 W/m² K | R = 25 db

Structure

V-Profile smooth

Outer color

according to the current offer of panels

Inner color

according to the current offer of panels

Finger pinch protection (FSP) | polyurethane foam core | hot-dip galvanized on both sides | U = 0.50 W/m² K | R = 25 db

Structure

Smooth without a groove

Outer color

according to the current offer of panels

Inner color

according to the current offer of panels

Finger pinch protection (FSP) | polyurethane foam core | hot-dip galvanized on both sides | U = 0.50 W/m² K | R = 25 db

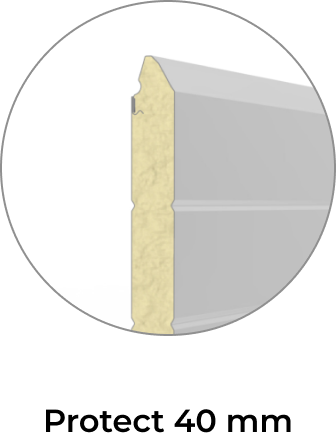

BIM models

- 3D models for use in the construction of houses for logistics centres

- models for industrial doors, garage doors, side entrance doors Mandoor

- the individual components of the structure are described using a 3D model dataset, with their properties

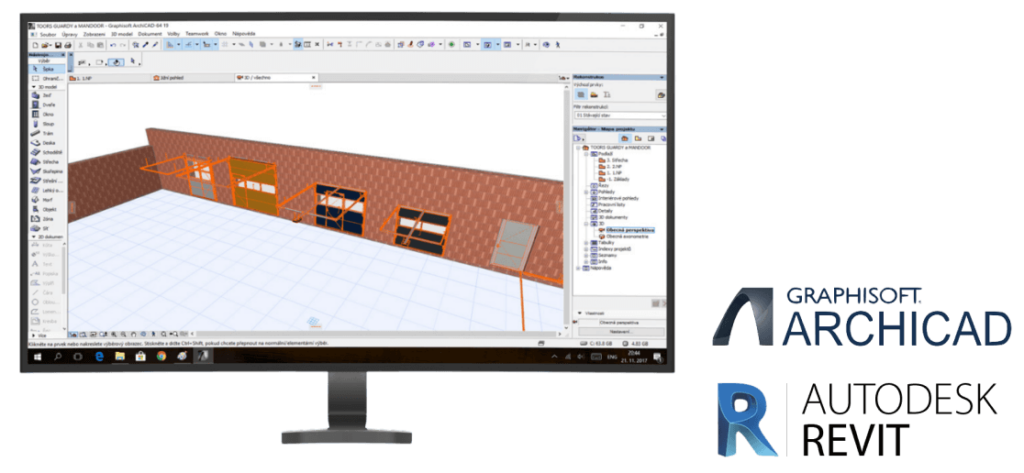

sTOORe – gate configurator

Configurator for all types of doors – industrial, garage, double doors, side doors in several languages

- quick and easy door specification

- price quotations and necessary documents for the doors immediately at hand

- visualization of configured ports

Logistics

As we are a manufacturing company, we focus on what we do best. That’s why we use strong and experienced partners in distribution logistics, for whom transport is their daily bread. Within our distribution network, we are able to deliver goods almost anywhere in the world. Our high-quality distribution network enables us to shorten delivery times and increase quality. We offer delivery and unloading services throughout the EU.

As a standard, we deliver doors within 1 calendar week after production and to the most remote locations within the EU within 2 weeks. By mutual agreement, we are also able to deliver goods (e.g. spare parts) within a few hours after production. We keep up with the times and strive to meet the current needs of our customers. Especially in the area of distribution logistics, which always has added value for our customers.